FacileAid™

Positioning Cradles

FacileAid™ can produce excellent posterior positioning cradles as

good as the cushions produced by the most well-known brand, Alpha CradleTM which was released since 1981 to RT market.

Simply mixing two contents, therapists can get custom rigid foam molds in about 15 minutes easily. Unlike posterior cradles made of vacuum bags

which frequently have unexpected flat problem, molds made from Facile Aid™ are rigid, light and permanent to keep the same contours /

dimensions during the whole treatment course. The finished mold can be customized by a utility knife to cut desired "ports" and drawn directly

on the molds for markings to aid in re-positioning for quality radiation treatments.

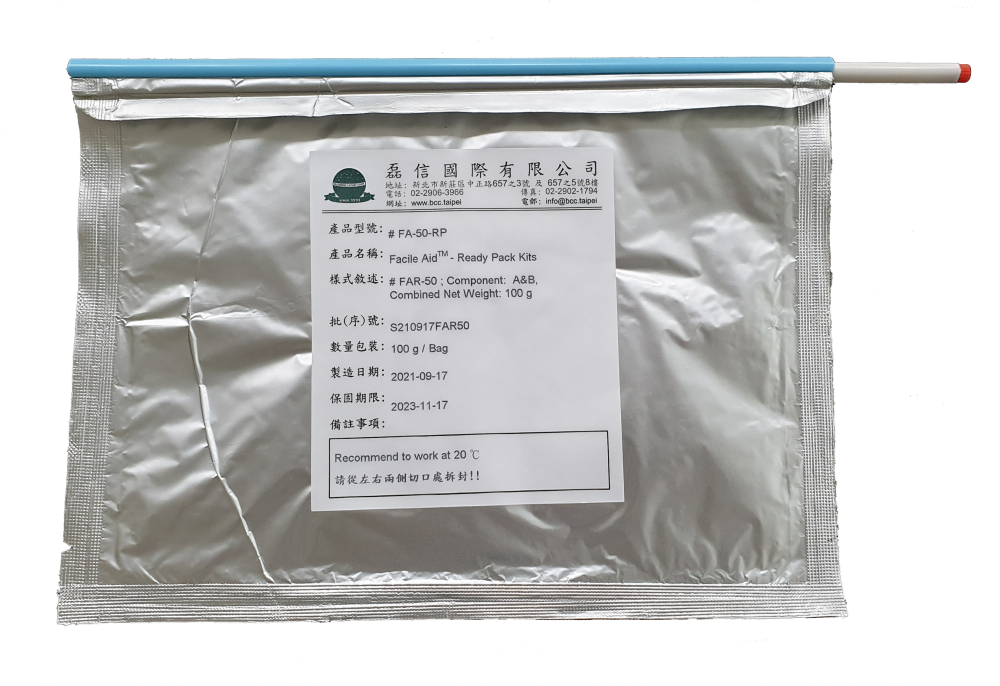

*** Operation-Friendly

Both bottle kits and ready-pack kits can help mold production in an easy and easy way. Its moderate curing time not only can avoid failure of molding

work but also can reduce the motionless discomforts of patients during molding.

*** Health & Environment-Friendly

Due to no volatile organics in the formula, our products have no offensive odor and no inhalation hazard to technicians and patients during the whole

production process. In addition, the fire retardant inside can effectively reduce smother emitted from burning foam in case an accidental fire happens

or during garbage disposal.

*** Clinical-Proven

FacileAid™ kits release the least heat during molding process to make patients get maximum comfort. Besides, due to the proprietary formula, the

finished cradles have less broken problems and the least shrinkage, consequently, can get maximum repositioning accuracy for treatments.

Custom foaming speed or weight for personal preference are available.

Custom head / neck cushion made from # FAB-60 shown with Type-S Overlay and a large S-Frame mask docking by T-shaped push / pull pins.

# FAB-170

The bottle pack kit comes with T-shaped nylon bag and can be used to produce a foam cradle while using S-Frame masks.

Breast Cradle made from

# FAB-600.

Pelvis Cradle made from

# FAB-600

# VBF-002 VacBag™ Fixer

The VacBag fixer was designed to be an economy re-positioning aid of Vacuum Bags on couch. But it is also ideal to put beneath patient

body while using two-part foaming agents to increase the thickness of the foam cradles.

The fixer is shown with a carbon fiber lock bar for IPPS™ above.

# FAMM-CV Mold Maker (Classical Version)

Using this classical mold maker, custom comfortable foam cradles with perfect contours can be created to increase patient comfort and the

accuracy of repositioning during treatment.

Each Mold Maker comes with 1 baseplate and 23 ea. wooden dividers. The baseplate is made of heavy-duty resins and has built-in handle for

easy transfer with gross weight about 7 kg only. The wooden dividers are made of light wood and can help the technicians control the molding

process in a manageable and efficient way.

By courtesy of Mackay Memorial Hospital Taitung Branch

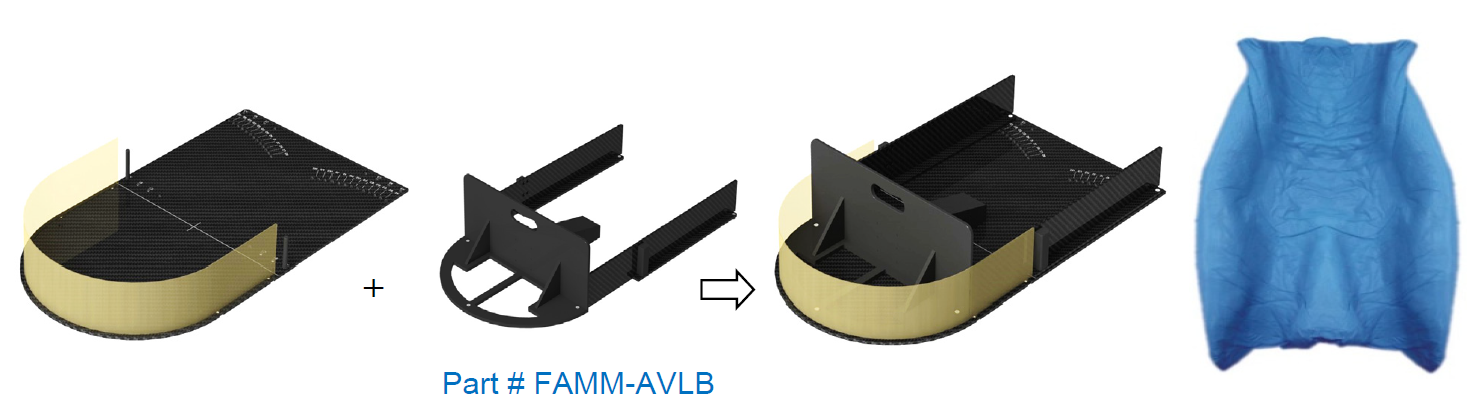

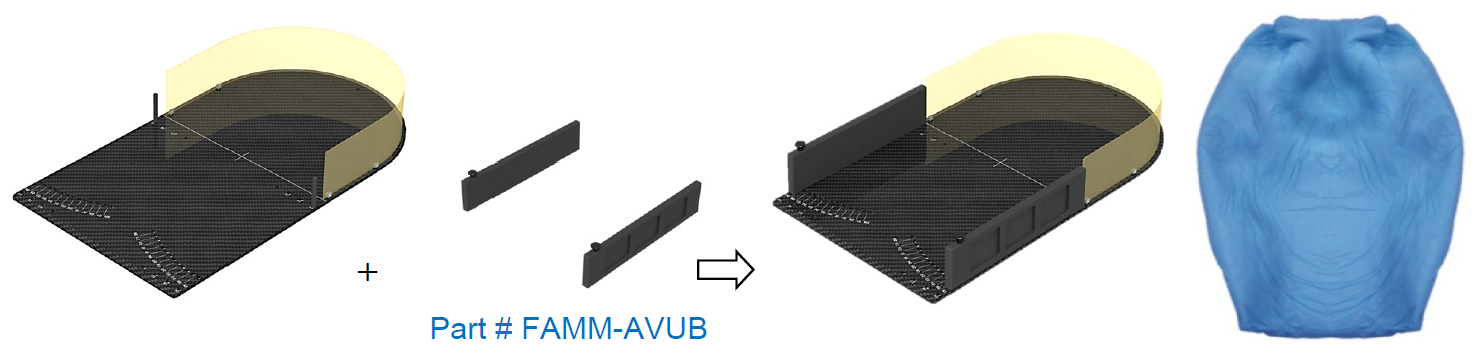

# FAMM-AV Mold Maker (Advanced Version)

The Advanced Mold Maker was designed by Koo Foundation Sun Yat-Sen Cancer Center in Taipei and has been proven for clinical use for more

than two decades. The system consists of one carbon fiber baseplate and two plastic modules for the posterior mold production of upper body

or lower extremities. The plastic semi-circular restrainer on the baseplate can help the technicians control the posterior molds in a

desirable size for imaging and treatment.

Simply using the baseplate along with upper body or lower body module as the photos shown below, therapists can create custom posterior molds

with perfect contours by two-part foaming agents or vacuum bags to improve patient comfort and the accuracy of repositioning for treatment.

(a) Production for Upper Body Mold

(b) Production for Lower Body Mold